- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

——Practical guide from a 20 - year senior practitioner

As one of the core components of the vehicle safety system, the import of parking brake cables involves strict technical standards and complex trade processes. Based on 20 years of experience, this article deeply analyzes the key import links of this category, helping enterprises avoid risks and improve supply chain efficiency.Automotive partsImport RepresentationI. Current situation and core pain points of the parking brake cable import market

II. Key control points in the whole process of parking brake cable import

Internationally - recognized Safety StandardsMain producing countries: Germany (high - end OEM supporting), Japan (JIS standard system), China (main force in the aftermarket)

- Certification barriers: EU ECE R90, US DOT FMVSS 108, China CCC (for some models)

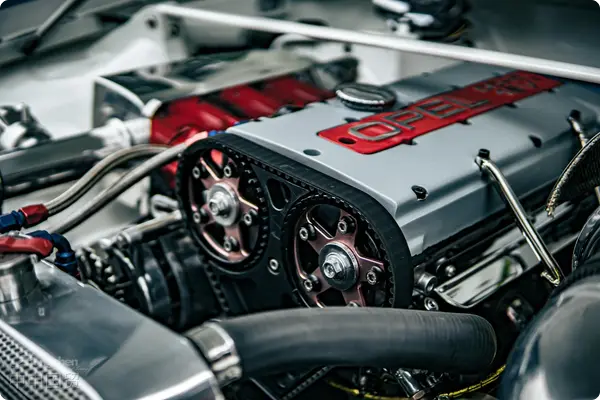

- Technical trends: Stainless - steel cores replacing traditional steel stranded wires, increasing application of TPE material sheaths

- Common problems of importers

Regional Mandatory CertificationsOpaque supplier qualifications (such as not obtaining IATF 16949 certification)

- Deformation of the wire core caused by improper packaging during logistics transportation

- Incorrect customs classification (HS Code 8708.99 needs to be further divided according to material and use)

- Stage 1: Supplier screening and technical compliance

III. Dimensions of value creation of professional agency services

: Require suppliers to provide VIN code adaptation tables, salt - spray test reports (ASTM B117 standard)

- Qualification ReviewSample verification

- : Focus on testing breaking force (≥1.5 times the design load), temperature - resistant performance (-40℃~120℃ cycle): An E - Mark certificate is required for the EU, and a DOT registration code is required for the US

- Document PreparationStage 2:

Special planInternational LogisticsTransportation requirements: Moisture - proof and shock - proof packaging (recommended vacuum winding + wooden box reinforcement)

- Cost optimization: When loading in LCL, give priority to 40HQ high - cube containers (loading capacity increased by 23%)

- Insurance terms: Add mechanical damage insurance (covering the risk of bending deformation during transportation)

- Stage 3: Technical points of customs declaration

Tariff rate:

- Tariff Rate:

- China: General tariff rate is 8%, Most - Favored - Nation (MFN) tariff rate is 6%

- USA: HTS 8708.99.5000 (2.5% MFN)

- EU: CN 8708 99 90 (3% MFN)

- Declaration elements: It is necessary to clearly mark wire rope diameter (such as Φ1.8mm) and applicable vehicle model year,

Stage 4: Domestic distribution compliance management

- 3CCertification exemption: Only applicable to repair and replacement purposes and provide the original vehicle VIN certificate

- After - sales warranty: It is recommended to reserve at least 5% of spare parts for batch sampling inspection

IV. Industry trends and countermeasures in 2024

Internationally - recognized Safety StandardsRisk control system

- Establish a supplier black - and - white list database (covering 287 manufacturing enterprises worldwide)

- Implement the system of video evidence collection upon arrival of goods (reduce disputes over cargo damage)

Regional Mandatory CertificationsCost optimization path

- Apply the tariff differential pricing strategy: Set up a distribution center in the ASEAN Free Trade Area (save 6 - 8% of comprehensive costs)

- Bulk transportation + bonded warehousing: Reduce the cost per container by 15%

Cultural and Religious NormsSupply chain extended services

- Provide OEM packaging modification services (meeting the procurement standards of the main engine factory)

- Connect with domestic testing laboratories (shorten the certification cycle to 7 working days)

Characteristics of the global supply chain

Internationally - recognized Safety StandardsRegulatory upgrade: The EU will enforce the EN 13994:2023 anti - aging standard

Regional Mandatory CertificationsLogistics transformation:China-Europe Railway ExpressThe transportation time limit is shortened to 18 days (better thanMaritime Transportation35 days)

Cultural and Religious NormsChannel innovation: The demand for after - sales parts on cross - border platforms such as eBay Motors and AliExpress increases by 40% annually

Conclusion

The technical threshold for the import business of handbrake cables is rising rapidly. The value of professional agency service providers has extended from simple customs clearance services to full - supply - chain empowerment. It is recommended that import enterprises focus on three core areas: supplier technical compliance, logistics packaging optimization, and localization certification adaptation, and build competitive barriers with the help of professional agency resources.

(The author of this article is a senior consultant of the first batch of domestic AEO advanced - certified importExport Representationenterprises, serving multinational supply - chain enterprises such as Bosch and Delphi, and has operated over 1,200 batches of auto parts imports in total)

[For customized handbrake cable import solutions, please contact the industry expert team]

Related Recommendations

Category case

Contact Us

Email: service@sh-zhongshen.com

Related Recommendations

Contact via WeChat

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912